When Pete Hegseth visited Divergent’s factory in Torrance, California, earlier this month, the plan was simple: a brief 30-minute walkthrough. What followed instead was a more than two-hour deep dive into one of the most ambitious manufacturing transformations underway in the United States today.

The Secretary of War was captivated by what he saw—Tomahawk missile structures, helicopter components, luxury car chassis, and advanced defense systems being designed, printed, and assembled under one roof using state-of-the-art 3D printing and AI-driven engineering. Processes that once took years can now be completed in weeks, sometimes even days.

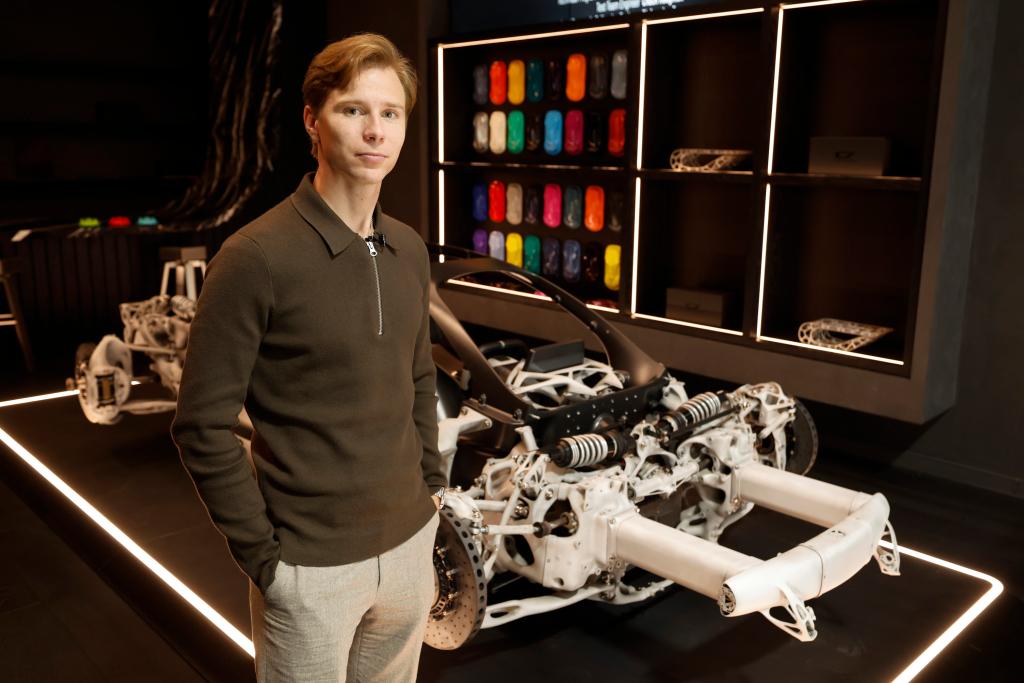

“Our mission for ten years has been to build the 21st-century industrial base,” said Lukas Czinger, Divergent’s 31-year-old CEO. “Divergent was founded to build a new way of engineering and manufacturing.”

A New Model for Industrial Production

Founded in 2014 by Kevin Czinger, a former Goldman Sachs executive who later moved into electric vehicles, Divergent was born out of a belief that traditional manufacturing had become too slow, fragmented, and inefficient. His goal was to pioneer a fundamentally new approach—one that could restore speed, flexibility, and resilience to American industry.

Today, Divergent specializes in AI-powered design and advanced 3D printing of complex metal structures, serving both defense giants such as Lockheed Martin and Raytheon and elite automotive brands including McLaren, Bugatti, and Aston Martin.

What truly sets Divergent apart is its end-to-end vertical integration. The company can take a concept—either its own or a client’s—design it using AI, print components on custom-built 3D printers using proprietary aluminum powder, and assemble the final product with robotic systems in the same facility, often on the same day.

“There wasn’t a company that stitched together the full environment before us,” Lukas explained.

Speed, Scale, and Strategic Advantage

Divergent’s custom printers are three times faster than comparable systems on the market and can produce single components as large as 2.3 feet by 2.6 feet. Once assembled, finished structures often exceed 13 feet in length.

This speed enables rapid iteration—new versions can be printed overnight to correct flaws or enhance performance. Once a design is perfected, production scales quickly. A single printer can manufacture 400 munition structures per year, and Divergent currently operates 14 printers, with plans to expand significantly.

Housing the entire supply chain under one roof also delivers major cost advantages, reducing transportation, fuel use, and logistical delays.

“You end up with a product that is higher performing, cheaper per unit, and reaches the market in a fraction of the time,” Lukas said.

Manufacturing as Deterrence

Divergent’s capabilities have drawn attention at the highest levels of government. The company’s rapid manufacturing model aligns closely with a “peace through strength” approach to defense.

“The factory is the weapon—just having the capacity to produce is deterrence,” Lukas noted. “That alone can change the arc of competition.”

The company’s high-powered printers are also mobile, meaning they could potentially be deployed globally to manufacture components closer to conflict zones—reshaping the future of military logistics.

From Defense Tech to a $3 Million Hypercar

While Divergent’s technology powers critical defense systems, it also underpins some of the most exclusive vehicles in the world. The company’s own Czinger 21C hypercar, unveiled in 2020, remains in production today with a price tag of $3 million. Built using Divergent’s manufacturing system, the car represents a fusion of extreme performance and next-generation engineering.

Despite its ultra-luxury positioning, Lukas believes the technology’s true impact will be felt in the mass market.

“Affordability in the US is something that Divergent can enable for mass-market auto in the future,” he said, adding that just as the company has reduced costs in defense manufacturing, scaling production could bring down automotive prices as well.

Betting on Hardware Before It Was Fashionable

Divergent’s rise marks a dramatic turnaround from its early years. When the company launched, most Silicon Valley investors were focused on software—apps, platforms, and social media unicorns. Hardware, particularly domestic manufacturing, was widely seen as unattractive.

“It wasn’t attractive to do hardware,” Lukas recalled. “And if you were doing it, investors wanted to see an outsourcing strategy. We had to bring in investors who understood the vision—and were true patriots.”

That long-term bet has paid off. Divergent recently raised $290 million in a Series E round, reaching a $2.3 billion valuation. The company now holds more than 600 patents, employs over 500 people, and is working on more than 40 Pentagon contracts. While leadership remains tight-lipped about a potential IPO, its growth trajectory has firmly established it as a cornerstone of next-generation manufacturing.

A Family Business Built on Trust

Lukas, who graduated from Yale University in 2017 with a degree in electrical engineering, joined the company full-time immediately after graduation. Working alongside his father, he says, has been a key advantage.

“It’s a level of trust and efficiency you can’t have with anyone other than your own blood,” he said. “That trust trickles down into the efficiency of the entire company.”

Competing on a Global Stage

Divergent has become one of the clearest examples of how technology could help rebuild America’s manufacturing capacity, particularly in competition with China, which currently accounts for 30% of global manufacturing, compared to the US’s 16%.

“The only way we win against China is to scale a next-gen model,” Lukas emphasized. “We’ve leapfrogged their capabilities. They don’t have the printers we have, the robotic cells, or the post-processing.”

Looking Ahead

Over the next decade, Divergent plans to build more than 100 factories across the United States. While expansion into other states is underway, Lukas remains firm that starting in California was the right decision.

Their Torrance facility—just 20 miles southwest of downtown Los Angeles—offers access to elite engineering talent, venture capital, and a dense defense-tech ecosystem that includes Anduril, Shield AI, Lockheed Martin, and Raytheon.

In an era defined by geopolitical competition, supply-chain fragility, and technological acceleration, Divergent is proving that the future of manufacturing is faster, smarter, and closer to home—and that factories, once again, may be among America’s most powerful strategic assets.